- (+91) 9137627832

- nilesh.riddhienterprise@gmail.com

- 218,Sagar Prabhat,Co-Op Industrial Estate, Dahisar Check Naka, Dahisar(East), Mumbai, Maharashtra, India. 400068

© 2020 Riddhi Enterprise. All Rights Reserved

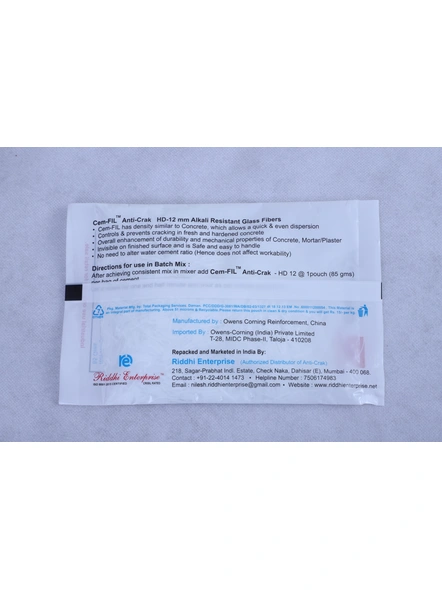

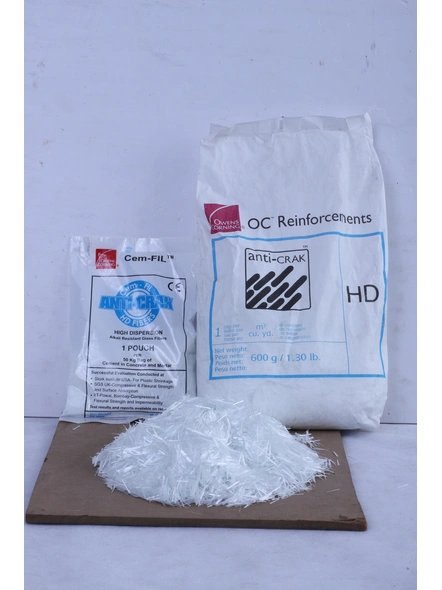

ANTICRAK HD FIBRE

Inclusive of all taxes

You Save: 35. Discount: 41.18%

-

Product is not available

concrete and all hydraulic mortars.

-

Additional Information

BENEFITS

Excellent workability

High Dispersion : 200 million

filaments per kilogram in fiber

length 12 mm

Invisible on the finished surface

Does not corrode

Control and prevention of cracking

in fresh concrete

Overall enhancement of durability

and mechanical properties of

concrete

Effective at very low dosage

Homogeneous mix

Safe and easy to handle

APPLICATIONS

Anti-Crak® HD fibers are typically used at low addition

level to prevent cracking & improve the performance

of concrete, flooring, renders or other special mortar

mixes. They incorporate easily into mixes creating a

tridimensional homogeneous network of

reinforcement in the matrix.

Anti-Crak® HD fibers can be added at the central

mixing plant to the wet concrete mix; or directly into

the ready-mix truck.

Anti-Crak® HD fibers do not protrude through the

surface and require no additional finishing

procedures. The reinforcement is incorporated in the

concrete mass and is invisible on the finished surface.

TECHNICAL CHARACTERISTICS

Fiber length-6mm/12mm

Filament Diameter (ISO 1888 : 2006)- 14 μm/0.00055”

Loss on Ignition (%) (ISO 1887 : 1995)- 0.60

Moisture (%) (ISO 3344 : 1997) - 0.50 max.

Electrical Conductivity: Very low

Specific Gravity: 2.68 g/cm3

Material: Alkali Resistant Glass*

Softening point: 860°C – 1580°F

Chemical Resistance: Very high

Modulus of elasticity: 72 GPa – 10 x 106 psi

Tensile Strength: 1000–1700 MPa – 145–250 x 103 psi (ASTM C1666 and EN15422) -

Reviews ()

Write a review